Have you ever wondered how silicone products are made? Well, let me introduce you to a game-changing technology called lsr molds. These molds have revolutionized the manufacturing process of silicone products and have become increasingly popular in various industries.

The Advantages of LSR Molds

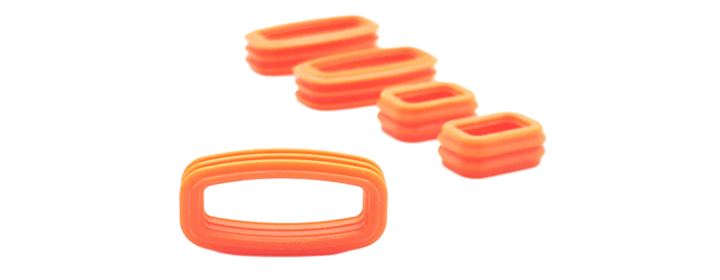

LSR (Liquid Silicone Rubber) molds offer numerous advantages over traditional molding techniques. Firstly, they allow for intricate designs and complex geometries that were previously impossible to achieve with other methods. This opens up endless possibilities for creating innovative and customized silicone products.

In addition, LSR molds provide exceptional precision and accuracy, resulting in consistent product quality. The liquid nature of the silicone material allows it to flow easily into even the tiniest details of the mold, ensuring every part is perfectly formed.

Furthermore, LSR molds enable faster production cycles compared to conventional methods. The curing time for liquid silicone rubber is significantly shorter than that of solid rubber materials used in traditional molding processes. This means manufacturers can produce more units in less time without compromising on quality.

The Rise of Overmolded Rubber

overmolded rubber has gained popularity as an application of LSR molds. It involves encapsulating one material with another by using two or more different types of silicones or combining silicones with other substrates like plastics or metals.

This technique offers enhanced functionality and durability to products by providing additional layers for protection against wear, tear, impact resistance, or improving grip surfaces. Overmolding also enables designers to incorporate multiple colors or textures into a single product seamlessly.

JVTECH: Pioneering Innovation in LSR Mold Technology

A leading player in the field of LSR molds is JVTECH, a renowned manufacturer known for its cutting-edge solutions. With years of experience and expertise, JVTECH has developed advanced molding techniques that push the boundaries of what is possible with silicone manufacturing.

They offer comprehensive services from design to production, ensuring that clients’ specific requirements are met. Their state-of-the-art facilities and skilled technicians enable them to deliver high-quality LSR molds that meet international standards.

Moreover, JVTECH stays up-to-date with the latest industry trends and continuously invests in research and development to provide innovative solutions for their customers. They have established themselves as a trusted partner for businesses seeking reliable and efficient LSR mold manufacturing.

In Conclusion

LSR molds have revolutionized the silicone manufacturing process by offering intricate designs, precision, faster production cycles, and consistent quality. Overmolded rubber applications further enhance product functionality and aesthetics. Companies like JVTECH play a crucial role in pushing the boundaries of LSR mold technology through innovation and exceptional service.